This is the story of how I fell down a rabbit hole made of plastic, precision, and a bit of Yoda wisdom

In 2017, I raced and smashed all my PBs. At the end of the season, I wanted to go faster. So I decided to marginal gain my bike.

I made a list of all the little improvements I could try—like taping over the bolts (they were allen key ones), or filling the gap between the tyre and rim with silicone. One thing I really wanted to do was remove the front mech since I never used it, but I didn’t want the chain to fall off.

I looked online for a chain guide that would work on a TT bike and found… nothing.

The guy who sat opposite me at work, Dan, was a maker. He had a lathe, a CNC machine, a 3D printer, and a laser cutter.

I asked him how he’d make a chain guide and he said, “I’d 3D print that.”

And I said, “Great. What’s a 3D printer?”

Dan was busy making incredible stuff, so I decided to give it a go myself.

How hard could it be?

Answer: very.

A glorious pile of strange pieces with no instructions.

I bought a 3D printer as a kit. It arrived in what felt like 2,000 pieces, and I spent a week of late nights assembling it.

At 3 a.m. on a Monday, I finally had all the cables plugged in right—and it worked.

Somehow, miraculously, all the pieces ended up in the right places. At 3 a.m. on a Monday, it finally came to life — belts whirring, fans spinning, ready to do the thing.

The first thing I printed was a flat disc.

Watching it move with such precision and build something from nothing right in front of me was incredible.

Not exactly the Mona Lisa, but these humble prints meant everything. Proof it worked. Proof I could do it. The disc was useless, the cube wasn’t quite square… but they were mine.

I loved them anyway.

I hadn’t told Dan I’d bought a printer.

That Monday, I handed him a calibration cube.

He said, “What’s this?”

I said, “It’s a calibration cube.”

He said, “I know. Why are you giving me one?”

I said, “I printed it.”

Dan was stunned. I’d built a printer and didn’t even ask for help.

From then on, Dan became my 3D printing Yoda.

He helped me get set up with CAD, talked me through problems when my prints went wrong, and shared techniques and ideas.

Dan was into figurines; I was into solving engineering problems.

That’s the thing about 3D printing—it’s big enough for both of us.

Eventually, after a crash course in CAD and many failed attempts, I created a working chain guide.

These are the early attempts at a chain guide. Each one lovingly designed with equal parts hope and cluelessness.

From the squared-off monstrosity on the left (what was I thinking?) to the sleek-ish one on the right that finally stayed on during a ride without trying to fling the chain into orbit.

By then, I already had a massive to-do list of things I wanted to print. At first it was all bike-related—marginal gains. Later it became brackets and tools for around the house.

Every design I made taught me something new.

Every new thing I learned gave me more ideas.

Creating designs created more designs.

It’s like the learning fed itself.

Then I started making actual things for inside the house.

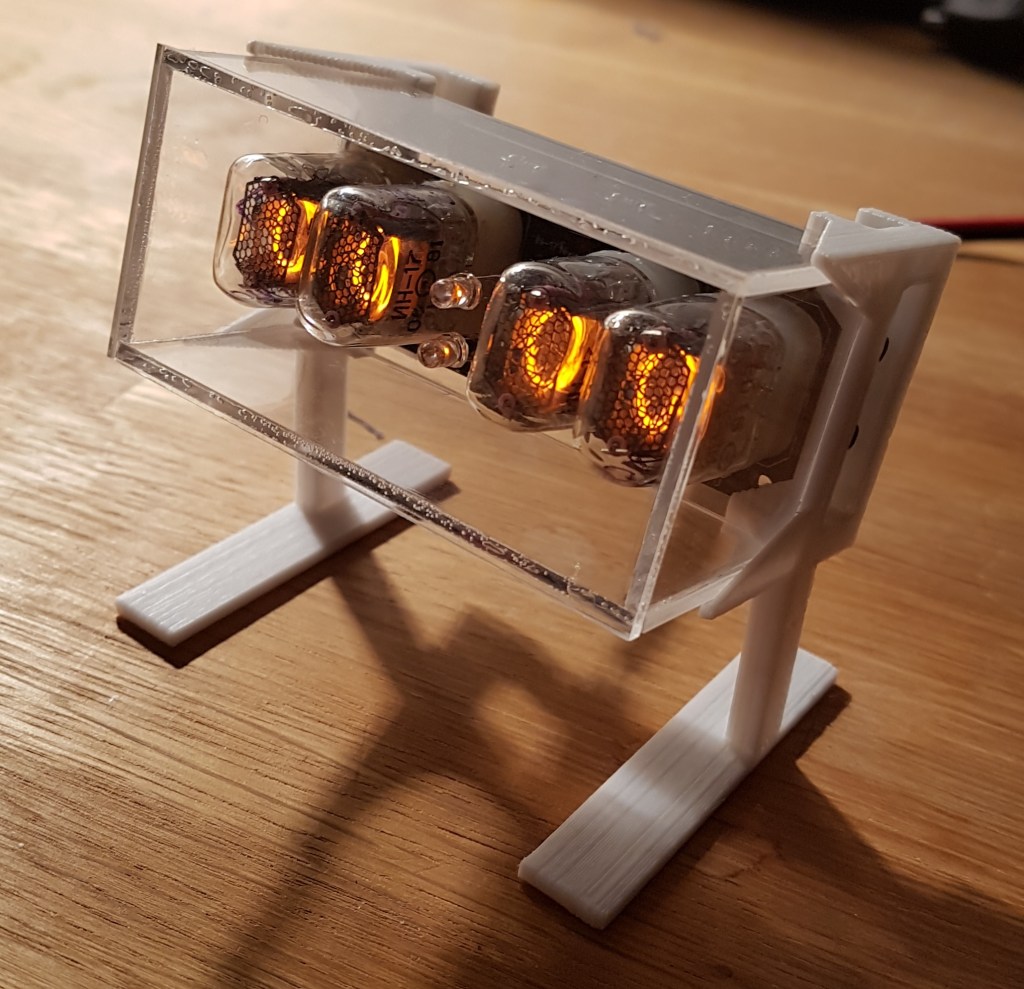

My first big one was a case for a Nixie clock. I had a cool idea, made it work, and I love the way it looks. I made one for my dad, and he loves it too.

Made the case myself. Designed it based off a dream I had.

It tells time, glows like a 1960s spaceship, and has absolutely no practical reason to exist.

Which is exactly why I love it.

I brought it into work to show Dan. I kept calling him my 3D printing Yoda, but when he saw the clock he said I’d surpassed him.

Dan made amazing things. He once recreated Ariadne’s bishop from Inception.

He spent ages studying film stills, designing the shape in CAD, and then used his lathe to carve it out of a brass cylinder.

It looked stunning. I told him he should sell them.

But he just shook his head and said he couldn’t stop seeing the tiny flaws and mistakes.

I couldn’t see them.

It looked perfect to me.

Later, Dan told me what he loved most about 3D printing: that he could make something just for himself.

He liked that there was only one of it in the world, and he had it.

He didn’t care what anyone else thought—it was his.

Eventually, I upgraded to a better printer and started designing bigger, more complicated things.

Dan’s way of thinking—about using 3D printing to create something unique and personal—rubbed off on me.

He was wrong about one thing, though.

I didn’t surpass him.

He’s still the best.

Some of the things he made, I don’t think I could have pulled off.

But he gave me something better than a benchmark—he gave me the passion for making.

I left that company not long after, and I miss my 3D printing Yoda.

I’m really glad I knew Dan.

He didn’t try to teach me everything. He didn’t push or preach.

He just shared what he loved, answered my questions, and nudged me in the right direction when I got stuck.

He helped me to persevere and to climb the near-vertical learning curve.

Sometimes the best thing you can give someone isn’t a thing—it’s a way in.

A quiet spark that sets something bigger in motion.

Dan gave me that spark.

Not everyone has a Dan. I think about that a lot.

And I try to be that person for other people now.

Everything I’ve designed since—I couldn’t have done it without him.

So my successes are his successes too.

And I like that.

Dan was also my Scrum Master Yoda.

But that’s a different story.

Leave a comment